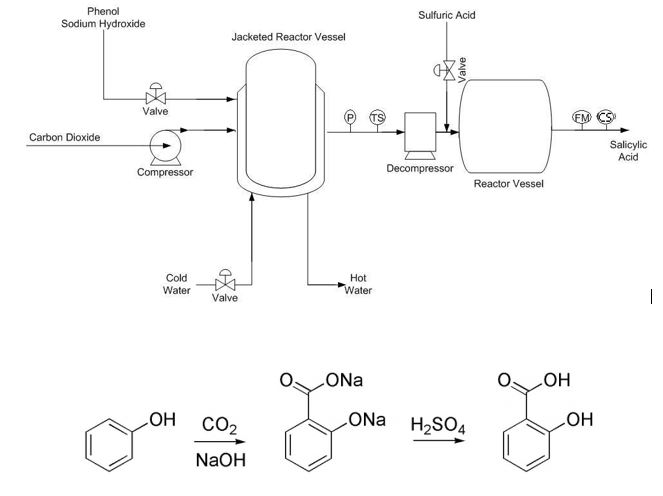

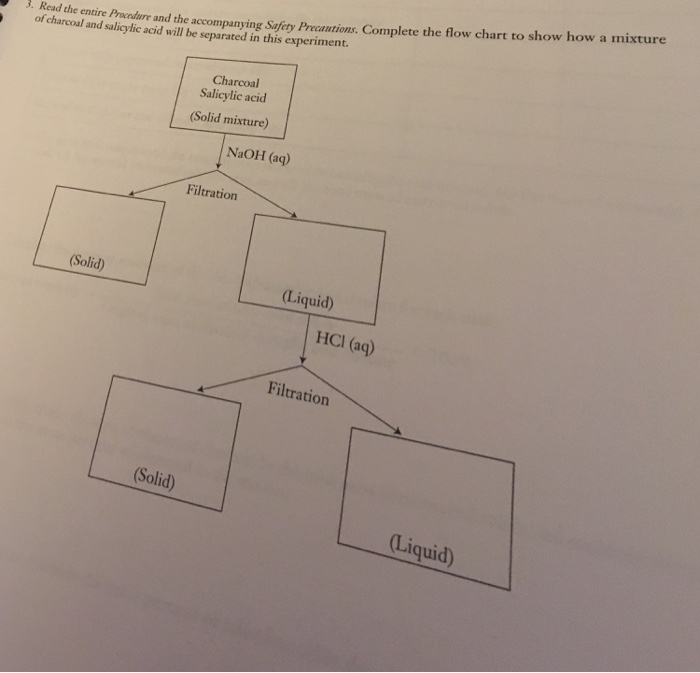

Process Flow Diagram Salicylic Acid

Subsequently the powder is subjected to high pressure carbon dioxide and producing sodium salicylate.

Process flow diagram salicylic acid. 2 acetyloxybenzoic acid o its molecular formula s. In the fume hood add approximately 3 5 4 0 ml of acetic anhydride to the flask containing the salicylic acid and stopper it. Wart removal usually isn t very painful but is uncomfortable. The center port on valve 1 was connected to.

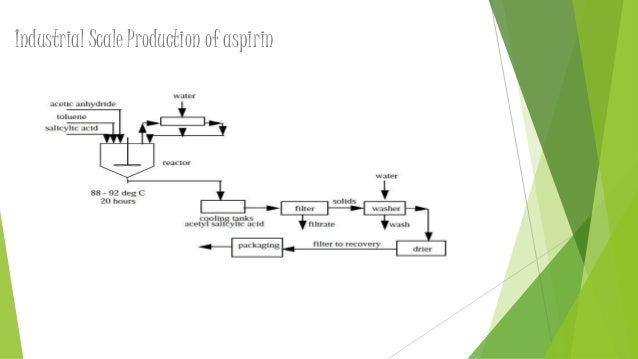

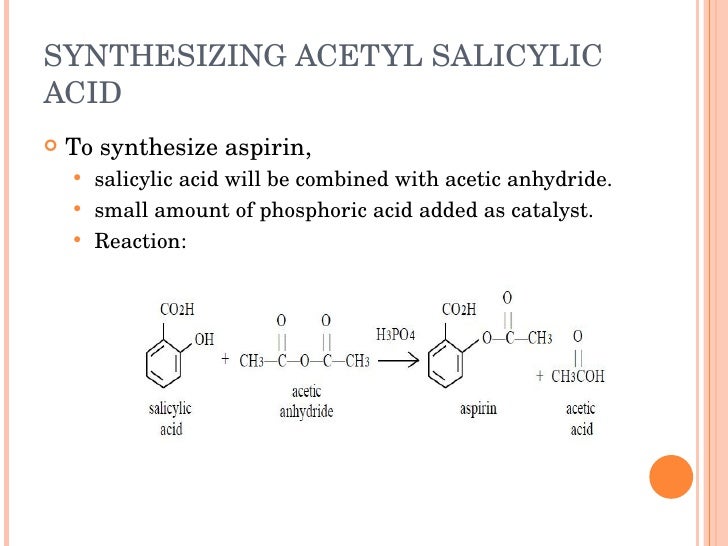

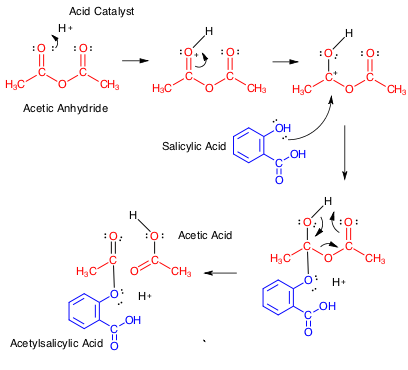

The salicylic acid is known to be a raw material for the manufacture of acetylsalicylic acid commonly known as aspirin. 1 2 3 4 analytical method development is a challenging and time consuming activity. The acid may cause the skin to discolor to a dark complexion but that is normal. Worldwide production of salicylic acid is roughly 60 000 metric tons yr.

Consult a dermatologist if salicylic acid does not work on warts after 12 weeks. Chemical process industr ies topic. Record the mass to the nearest 0 01 g. Salicylic acid from latin salix willow tree is a lipophilic monohydroxybenzoic acid a type of phenolic acid and a beta hydroxy acid bha.

The disclosed process makes possible a decrease in mass transfer limitations thereby enhancing production of acetyl salicylic acid. However discontinue when sores discomfort and irritation appears. Achieved at higher flow rates 3 to 5 times faster. O it is also commonly known by the name acetyl salicylic acid and its iupac name is.

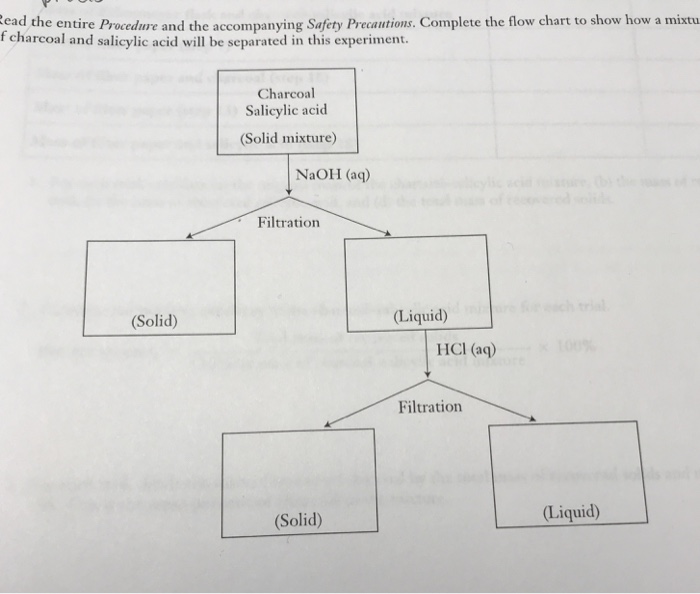

Salicylic acid is produced commercially via the kolbe schmitt process. Salicylic acid c7h6o3 it is obtained from the bark of the willow tree which is the substance used to be obtained is a monohydrobenzoic acid a type of phenolic acid and a betahydroxy acid. It requires planning experiments prepar. A sample consisting of salicylic acid and its published process impurities are sepa.

Here phenol and sodium hydroxide are reacted to make sodium phenoxide. Stages of wart removal using salicylic acid. The phenoxide is contacted with co2 to form sodium salicylate. A system for production of acetyl salicylic acid is also provided in which a reactor is.

Use of a high shear mechanical device in a process for production of acetyl salicylic acid by contacting acetic anhydride with salicylic acid in a high shear device. The salicylate is acidified to give salicylic acid. Preparation of aspirin prepared by. In the fume hood add five drops of concentrated acid to the flask containing the salicylic acid and acetic anhydride and swirl to mix everything thoroughly.

C9h8o4 and molecular weight is. The manufacturing process of salicylic acid starts with phenol and sodium to make dry powder of phenolate soda. Introduction and preparation of salicylic acid guided by by shibu g pillai 13bch012 asst. Gerhardt synthesized a primitive.

It has the formula c 7 h 6 o 3 this colorless crystalline organic acid is widely used in organic synthesis and functions as a plant hormone it is derived from the metabolism of salicin in addition to serving as an important active metabolite of aspirin. Preparation of aspirin 1.