Process Flow Diagram Of Reaction Injection Moulding

Reaction injection molding advantages.

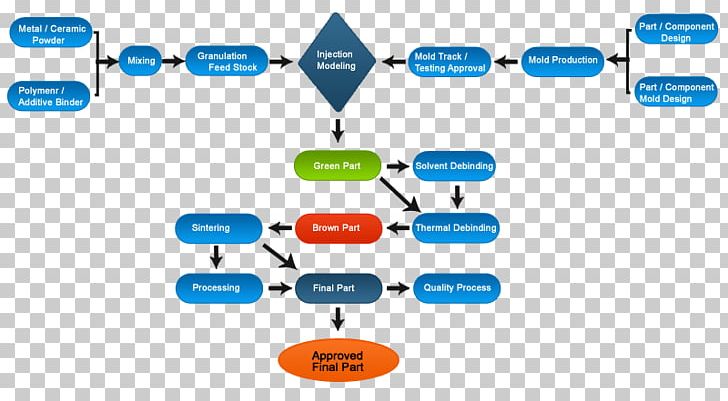

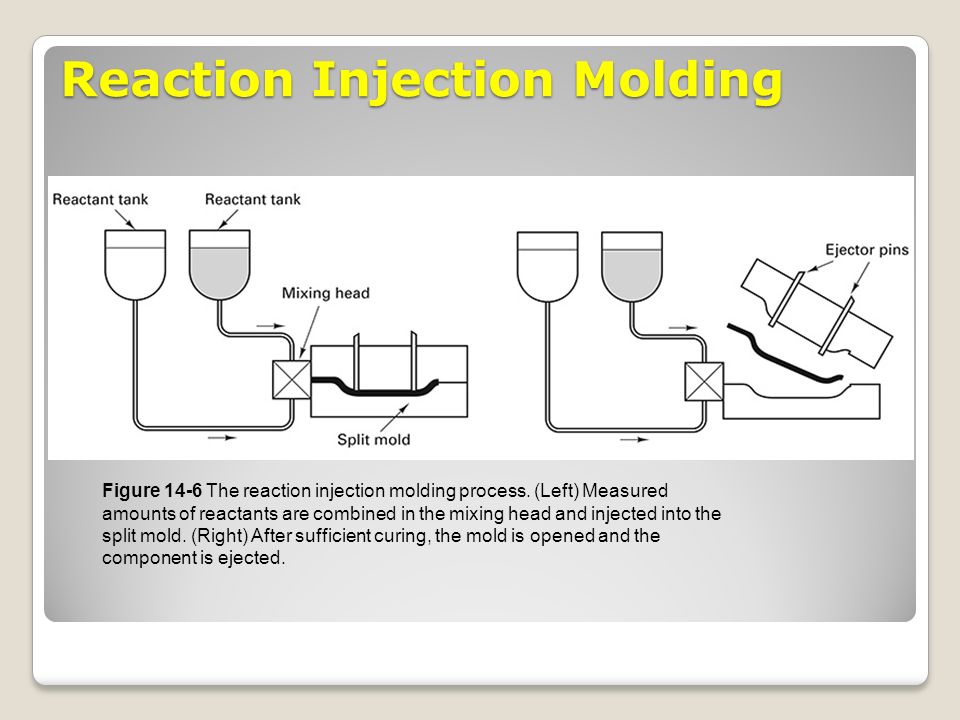

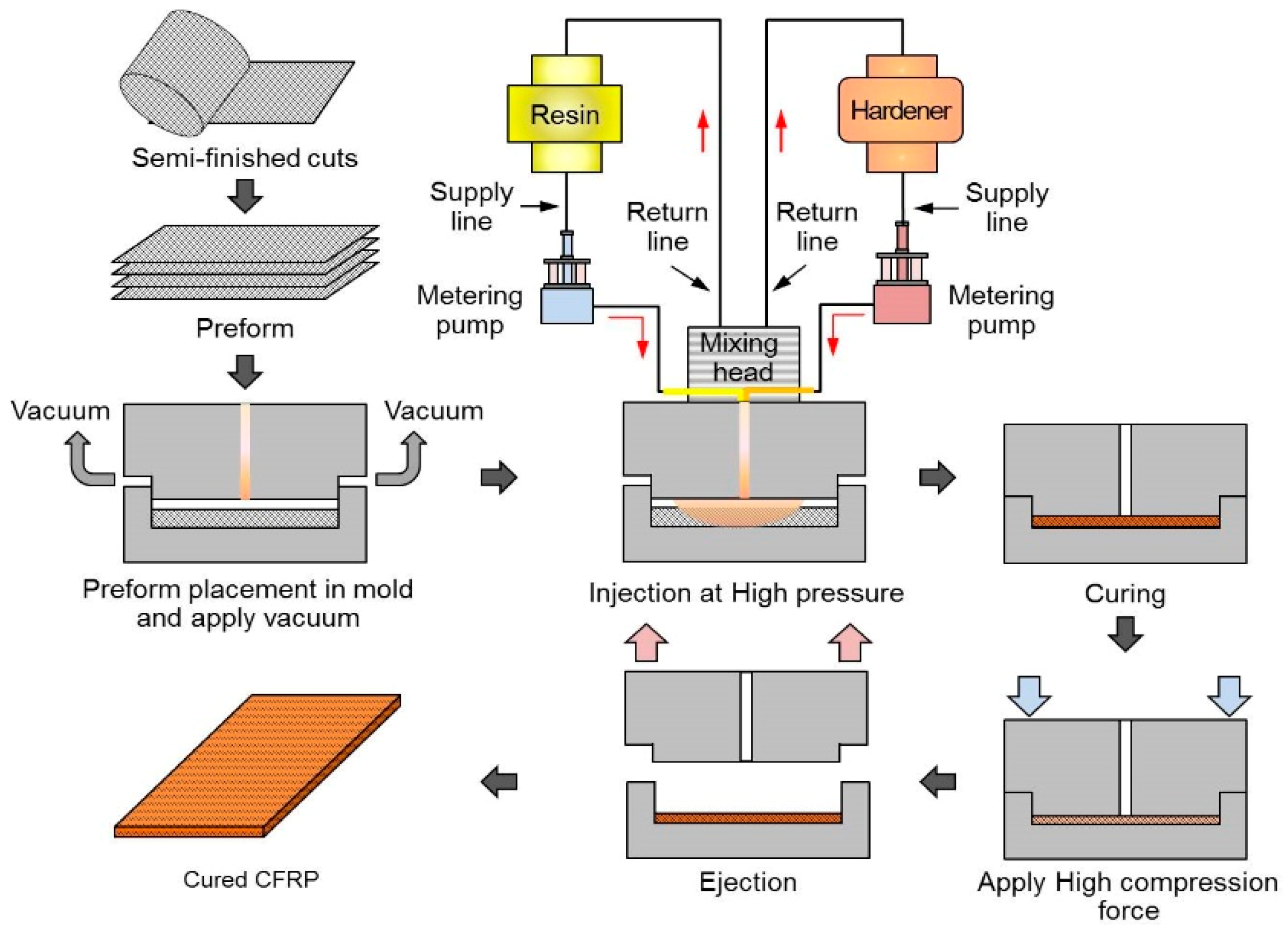

Process flow diagram of reaction injection moulding. When stage 3 is completed the mould closes again and the cycle starts over again. The fiber mesh is first arranged in the mold and then the polymer mixture is injection molded over it. Injection injection molding british english. There are three main stages in the injection moulding cycle.

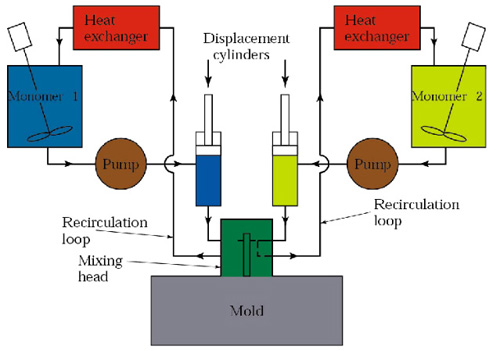

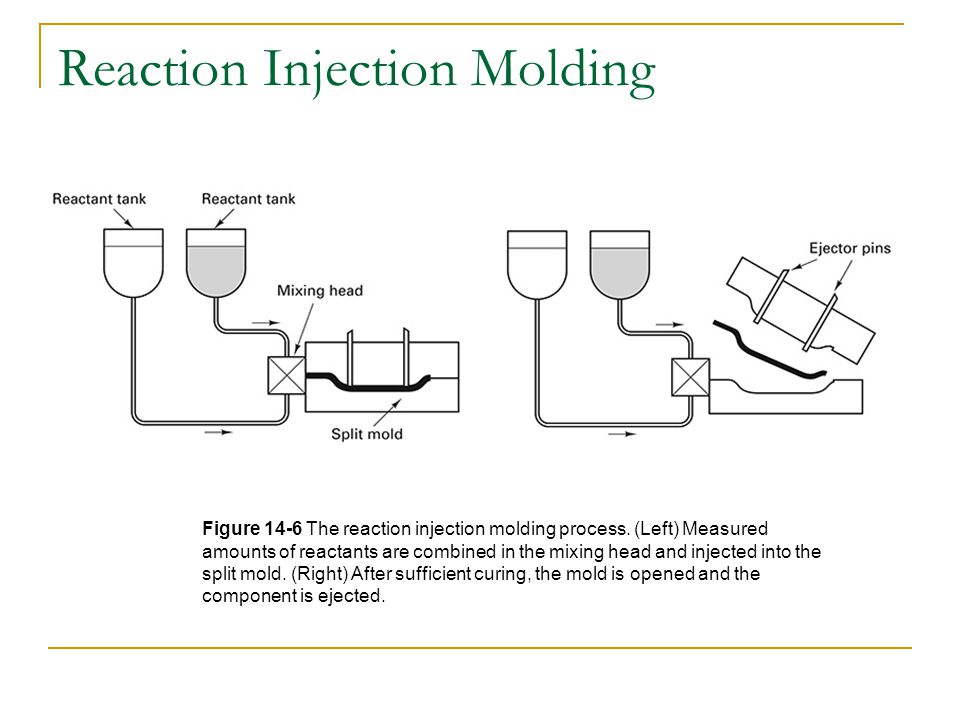

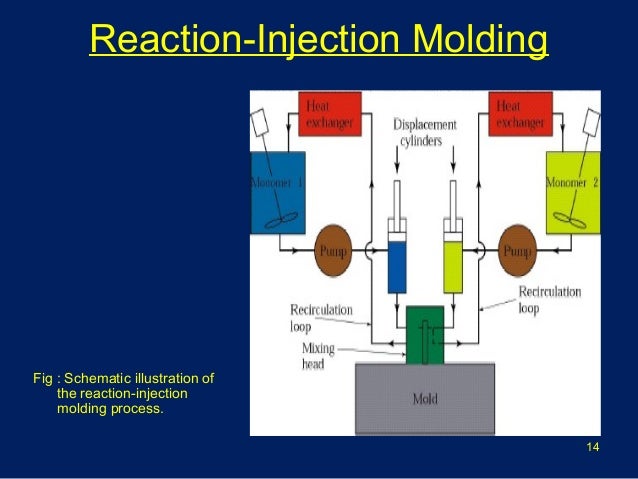

Material is fed into a heated barrel mixed and forced into a mold cavity where it cools and hardens to the configuration of the mold cavity. Stage 1 injection followed by stage 2 holding pressure and plasticating and finally stage 3 ejection of the moulded part. The admittedly longer production time of reaction injection molding is more than offset by its benefits to design flexibility and cost efficiency not to mention the wide ranges of part size. Shut mold filling mix max viscosity off mold curing eject post cure modulus gopt figurc 2 1 fill gel demold reaction time rhcological changcs during a rim cyclc adaptcd from.

Reaction injection molding is a simple concept. This process is usually used to produce rigid foam automotive panels. A reactive liquid mixture usually polyol and isocyanate is injected or poured into a mold where a chemical reaction takes place. Academia edu is a platform for academics to share research papers.

Reaction injection molding not only offers significant advantages over injection molding but also vacuum forming pressure forming and cast molding. A subset of rim is structural reaction injection molding srim which uses fiber meshes for the reinforcing agent. As its name suggests the process is based on a chemical reaction. Low viscosity large parts with thin sections are no problem.

Injection molding process data sheet injection molding process defects injection molding process description injection molding process development injection molding process diagram injection. Reaction injection molding advantages and disadvantages what is reaction injection molding machine. Injection moulding is a high production process of producing a vast variety of thermoplastic parts into shapes ranging from fairly simple to quite complex. Moulding is a manufacturing for producing parts from both thermoplastic and thermosetting plastic materials.