Process Flow Diagram Aiag

Team members process step.

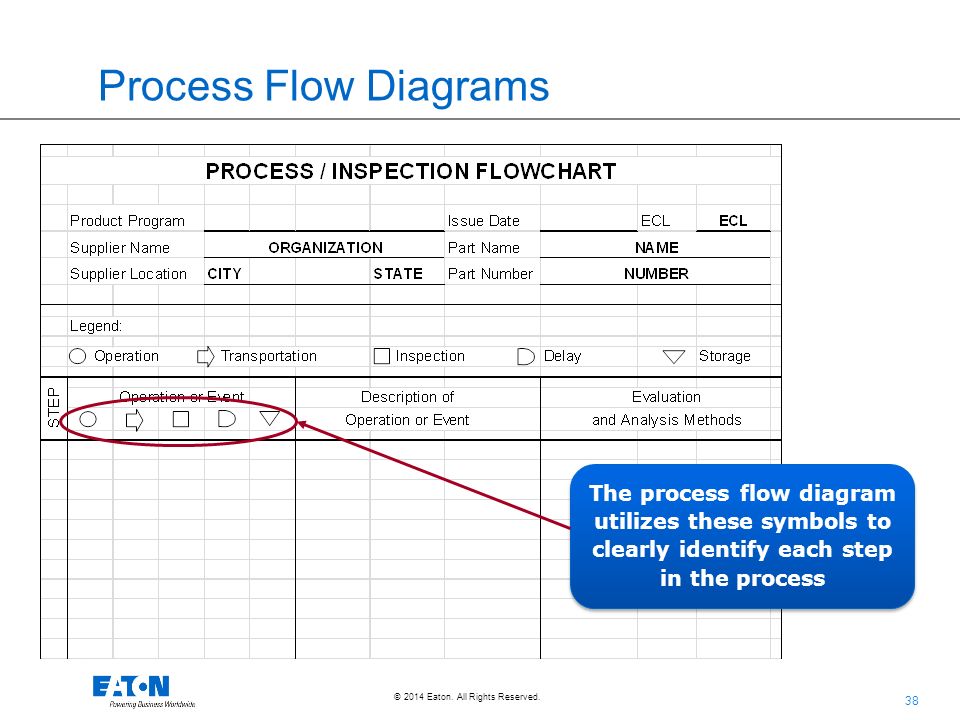

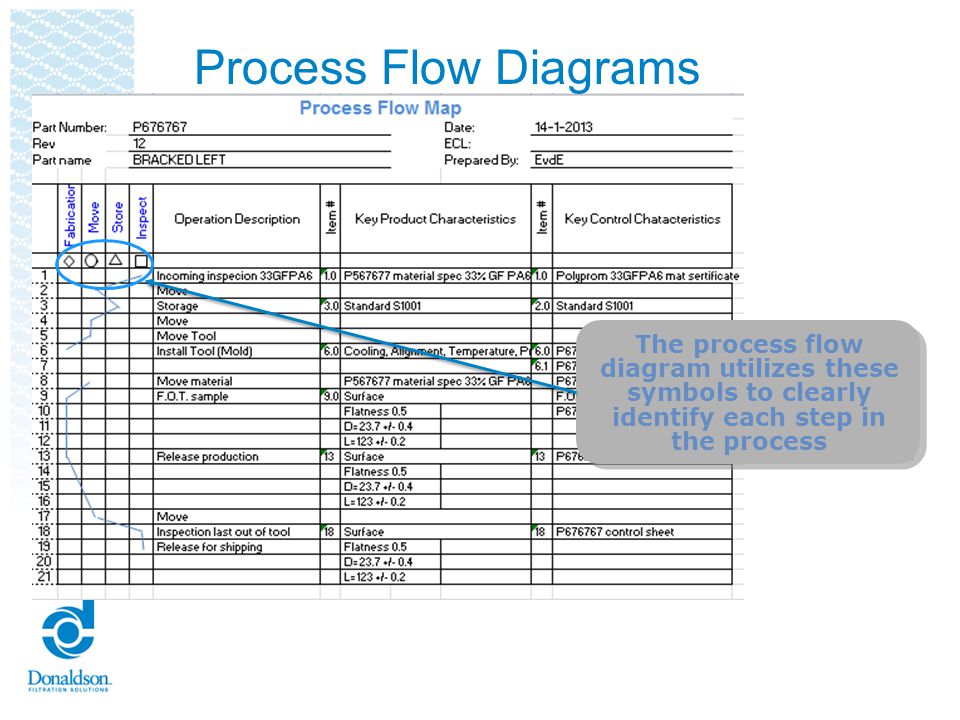

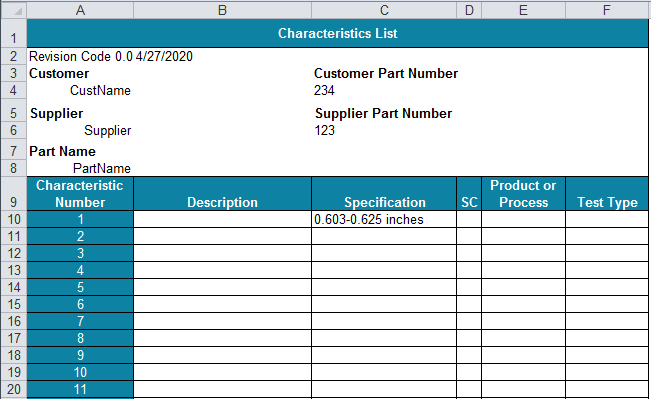

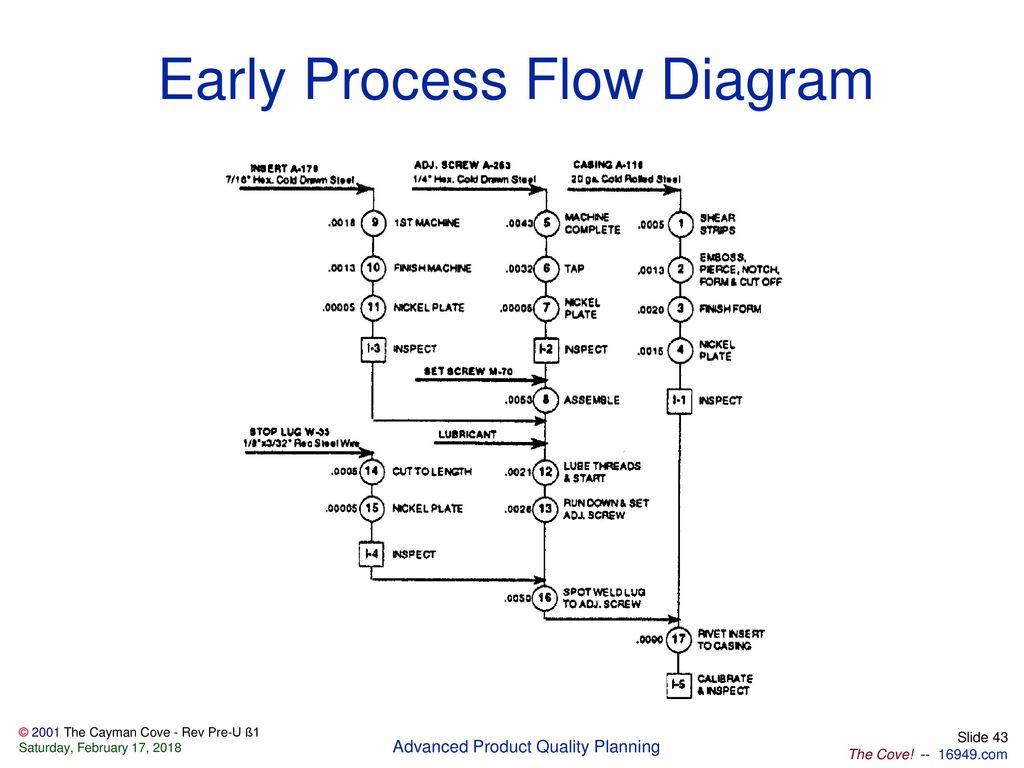

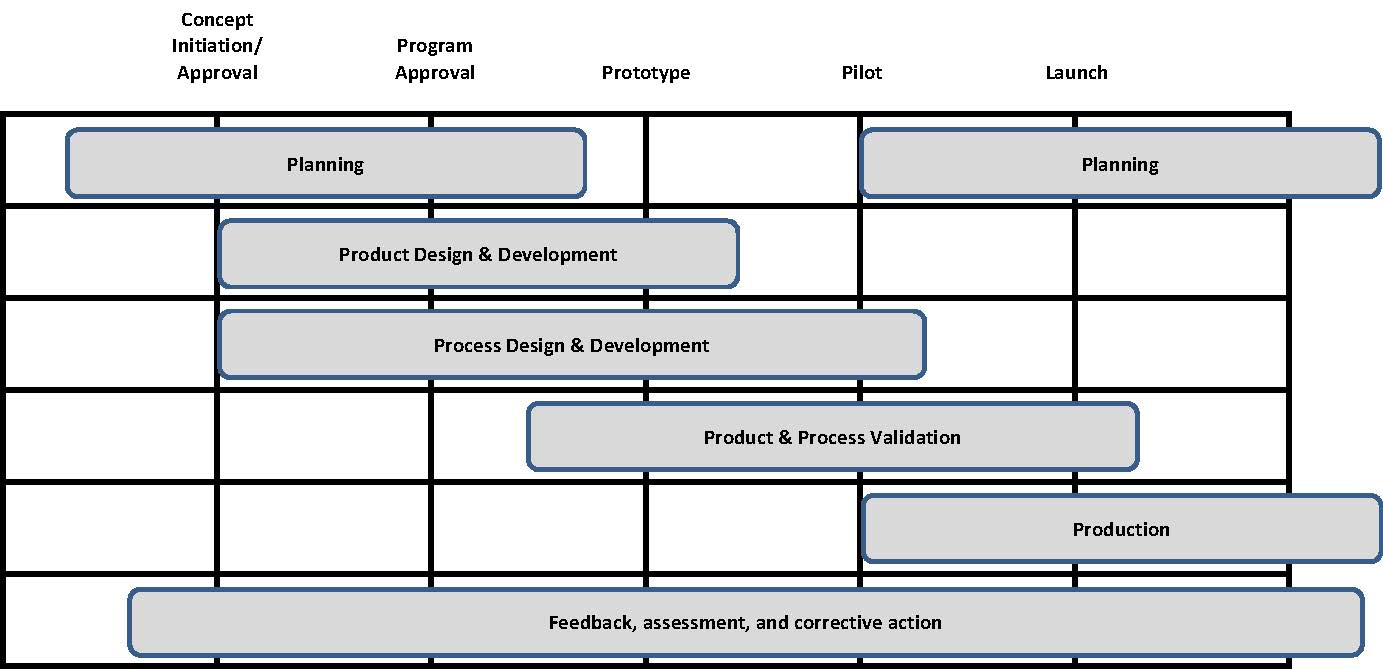

Process flow diagram aiag. Process flow diagram is the. Process fmea aiag fourth edition sae j1739 insert fmea name number of item responsibility. All stations shall be identified that create required design and process characteristics and shall match. Software solution to manage the consistency of process fmea control plan special characteristics and process flowcharts to remain in accordance with your trade specific references.

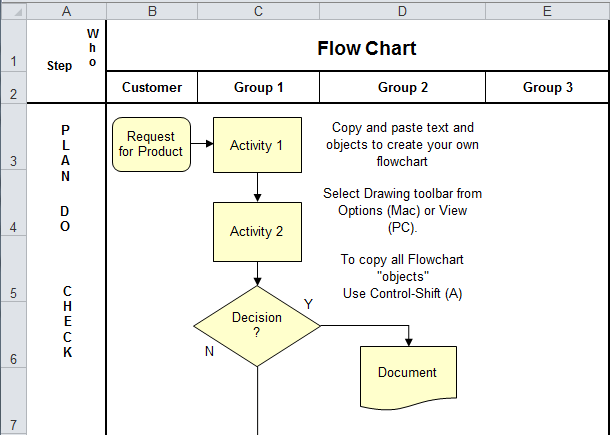

Process failure mode and effects analysis that will ensure product quality in the manufacturing assembly. The pfd displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Foundation the process must be defined step by step including. A process flow diagram pfd is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment.

The automotive industry action group aiag is a unique not for profit organization where oems suppliers service providers government entities and individuals in academia have worked collaboratively for more than 38 years to drive down costs and complexity from the automotive supply chain. The drop down scales are to be used as written in the aiag manual. Another commonly used term for a pfd is a flowsheet. The dfmea is a living document during the development process which means that throughout design development and testing as issues are identified they are included in the dfmea and corrective actions are documented.

Your process functions should correlate with the steps listed in the flow diagram and control plan. 2 2 5 process flow diagram assessment process flow diagram is a representation of the process flow diagram accurately reflects process rework and inspection. Production part approval process ppap is the industry standard that ensures engineering design and product specification requirements are met. Through the ppap guideline suppliers and customers understand the requirements to obtain part approval of supplier manufactured parts.

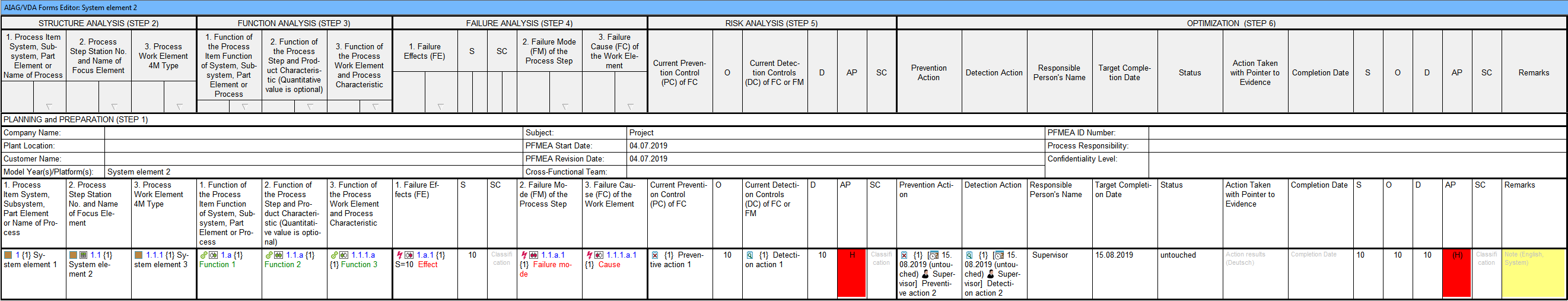

Will be in conformity with the aiag vda alignment when it will be official. The tables have been included in the list tab at the bottom for easy reference. Process flow diagram pfmea control plan product process change 4th design matrix 4th bulk materials reqts 4th performance test results 4th.