Process Flow Diagram Acetone

Figure 1 is also simplified.

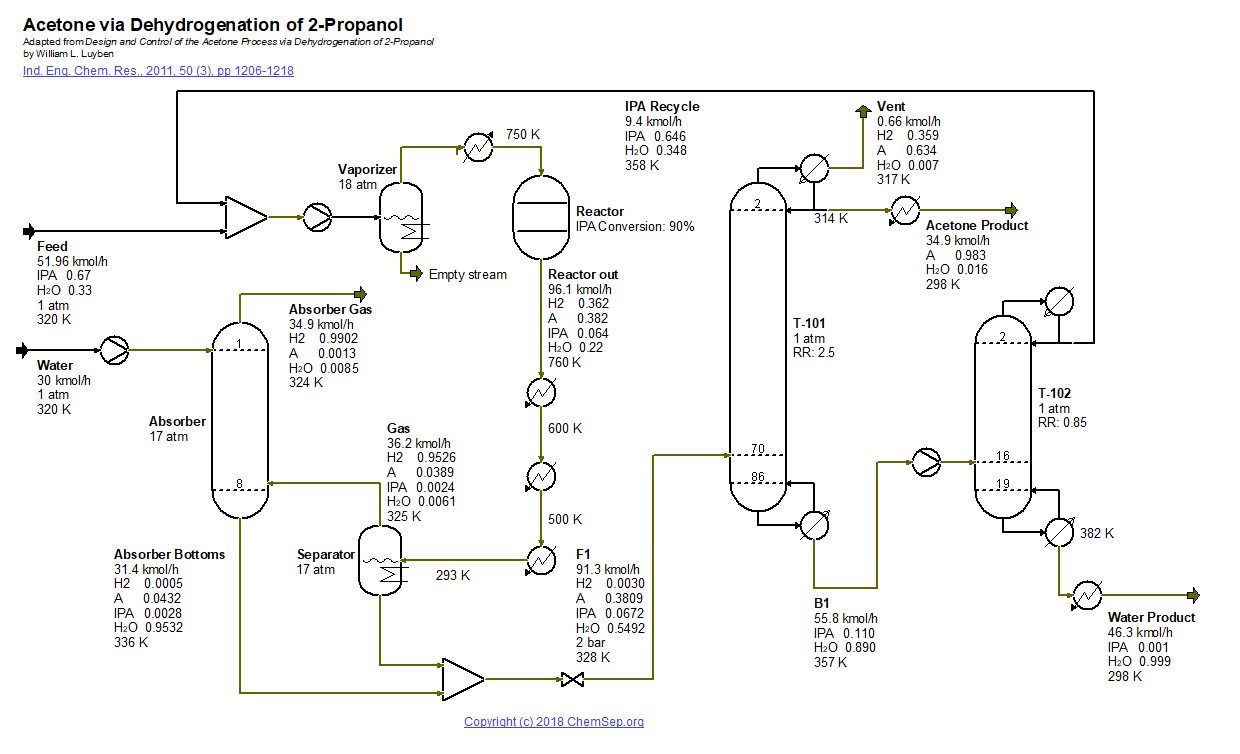

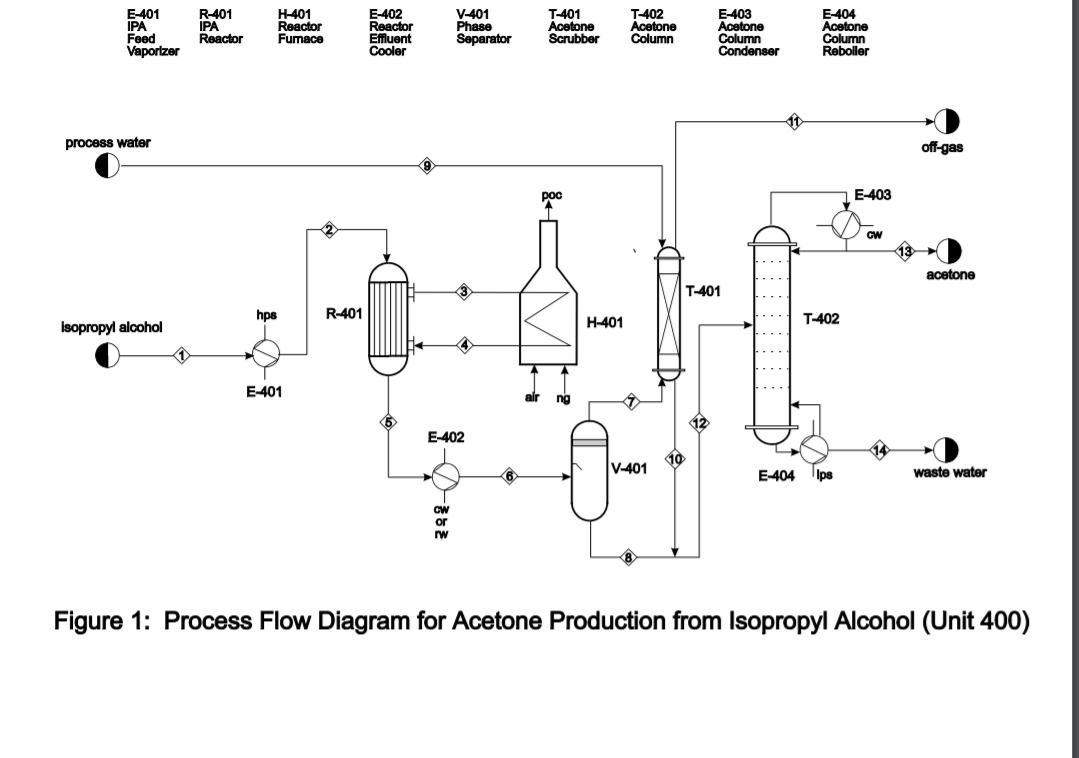

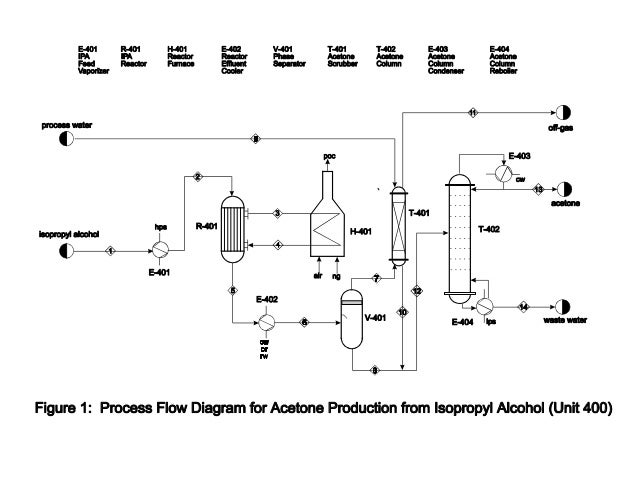

Process flow diagram acetone. Base process block diagram the base case study deals with the production of acetone from isopropyl alcohol by the. Process description figure 1 is a flow diagram of a simplified process for acetone production. The pharmaceutical industry is the process of catalytic dehydrogenation of isopropyl alcohol due to the high purity of the product. The isopropanol ipa feed is a near azeotropic mixture with water at 88 wt ipa at 25 c and 1 atm.

Present the process flow diagram pfd in figure 1 as a preliminary design. The main process for manufacturing cumene involves the reaction of propylene and benzene in the presence of phosphoric acid based catalysts or more recently zeolite catalysts. Full design for acetone production 1. Energy balances numerical methods design project production of acetoneprocess description figure 1 is a preliminary process flow diagram pfd for the acetone production process the raw material is isopropanol.

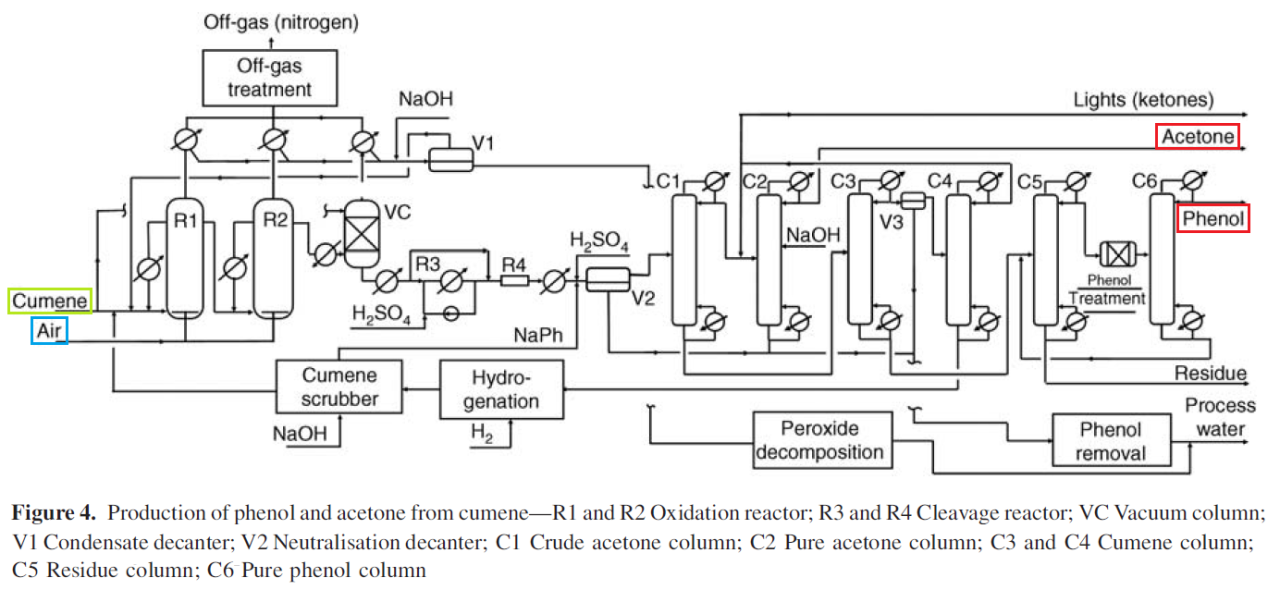

In 2008 global supply demand was relatively balanced as demand decreased because of the weakened global economy. The cumene route in which the acetone is coproduced with phenol is the preferred technology because of its lower costs and nearly 90 of acetone is produced this way. The reaction is endothermic. In particular pumps to raise the pressure and other equipment extraneous to the present level of design are not included.

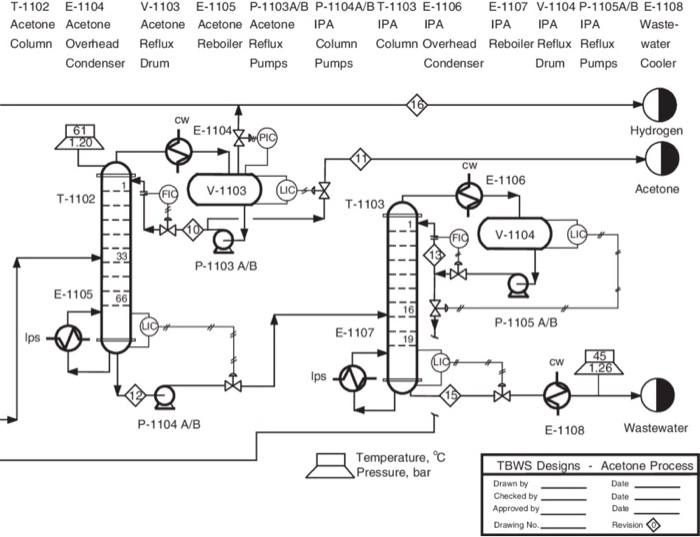

The production of acetone is 34 82 kmol h from a process feed of 34 82 kmol h of isopropanol representing an overall conversion of approximate ly 100. Acetone will be producing after 2010 in western europe. The produced materials from the reaction are acetone c3h6o and hydrogen h2 and the amount of acetone produced at 63346 kmol hr table 4 coul son et al 1999b. The acetone production.

In the simplified process an aqueous solution of isopropyl alcohol. Global ipa based acetone production is expected to decrease with the increase of phenol capacity acetone is a coproduct of phenol by the cumene peroxidation process. The heat is supplied to the plug flow reactor pfr via hot water at 700 k with hot water supplied from a fired heater. Us3330741a us34911164a us3330741a us 3330741 a us3330741 a us 3330741a us 34911164 a us34911164 a us 34911164a us 3330741 a us3330741 a us 3330741a authority us united states prior art keywords acetone column zone alkaline solution solution prior art date 1963 03 12 legal status the legal status is an assumption and is not a legal conclusion.

This process consists of a set of operations well known and used by process engineers. The raw material is isopropanol. Energy balances numerical methods design project production of acetone process description figure 1 is a preliminary process flow diagram pfd for the acetone production process.

.png)